Coal Gasification

Feedsee Energy : Coal Gasification : Plant will generate power and produce substitute natural gas

Coal gasification is a process that converts coal into a gaseous state, rather than burning it directly. The resulting gas, known as syngas or synthesis gas, can then be further processed to produce electricity, synthetic natural gas, or liquid fuels.

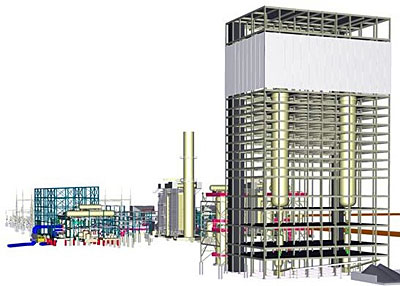

Kentucky's 630 net megawatt Cash Creek Integrated Gasification Combined Cycle facility is one of the most advanced and largest gasification projects under development in the United States. Gasification converts coal into a gas that is cleaned and then can be used to generate power or modified further to produce natural gas, hydrogen, or other basic chemicals. Relative to conventional coal-based power generation technologies, the project will produce fewer air emissions and use less water to provide power for 400,000 homes. The project's strategic location provides the flexibility to interconnect with three electric grids and is within six miles of major interstate gas pipeline connections, enabling efficient transport to end customers of the gas it will produce.

Kentucky's 630 net megawatt Cash Creek Integrated Gasification Combined Cycle facility is one of the most advanced and largest gasification projects under development in the United States. Gasification converts coal into a gas that is cleaned and then can be used to generate power or modified further to produce natural gas, hydrogen, or other basic chemicals. Relative to conventional coal-based power generation technologies, the project will produce fewer air emissions and use less water to provide power for 400,000 homes. The project's strategic location provides the flexibility to interconnect with three electric grids and is within six miles of major interstate gas pipeline connections, enabling efficient transport to end customers of the gas it will produce.

The process is usually conducted in a gasifier and typically involves the following steps:

- Drying and Grinding: The coal is first dried to remove moisture and then ground into a powder.

- Partial Oxidation: The powdered coal is mixed with a controlled amount of oxygen (usually less than needed for complete combustion) and sometimes steam, in a high-pressure, high-temperature environment within the gasifier. This results in a series of chemical reactions that convert the coal into a mixture of gases - primarily carbon monoxide and hydrogen, which is called syngas.

- Removal of Impurities: The syngas is then cleaned to remove impurities, such as sulfur and particulates, which can be processed and sold separately.

- Energy Production: The clean syngas can be burned in a gas turbine to produce electricity, converted into synthetic natural gas, or used as a feedstock to produce liquid fuels or chemicals.

Coal gasification has several advantages over conventional coal combustion:

- Increased Efficiency: Coal gasification systems can be more efficient than traditional coal-fired power plants, particularly when they are combined with gas turbines in what is known as Integrated Gasification Combined Cycle (IGCC) systems. This means they can generate the same amount of electricity from less coal.

- Emissions: Coal gasification allows for easier capture of pollutants like sulfur, particulates, and mercury that would otherwise be released into the atmosphere. Moreover, it also facilitates the capture and storage of carbon dioxide (CO2), a major greenhouse gas, which can potentially reduce the climate change impacts of coal use.

- Flexibility: The syngas produced can be used for various purposes - not just electricity, but also synthetic natural gas, hydrogen, or other chemical feedstocks.

However, there are also downsides:

- Cost: Gasification plants are expensive to build and operate, and the technology is more complex than traditional coal power plants.

- Water Usage: Gasification can use a significant amount of water, which could be a concern in areas where water is scarce.

- Carbon Capture and Storage: While gasification makes CO2 capture easier, the long-term storage of CO2 is still a challenge and can add to costs.

- Coal Extraction Impacts: Gasification doesn't eliminate the environmental and health impacts associated with coal mining.

While coal gasification presents a potentially cleaner way to utilize coal, the long-term viability and environmental advantage of the technology largely depend on the successful implementation of carbon capture and storage, and comparison with increasingly cost-effective renewable energy sources.